Why Polystyrene Is the Preferred Material for ELISA Plates

The Dominance of Polystyrene in ELISA Plate Manufacturing

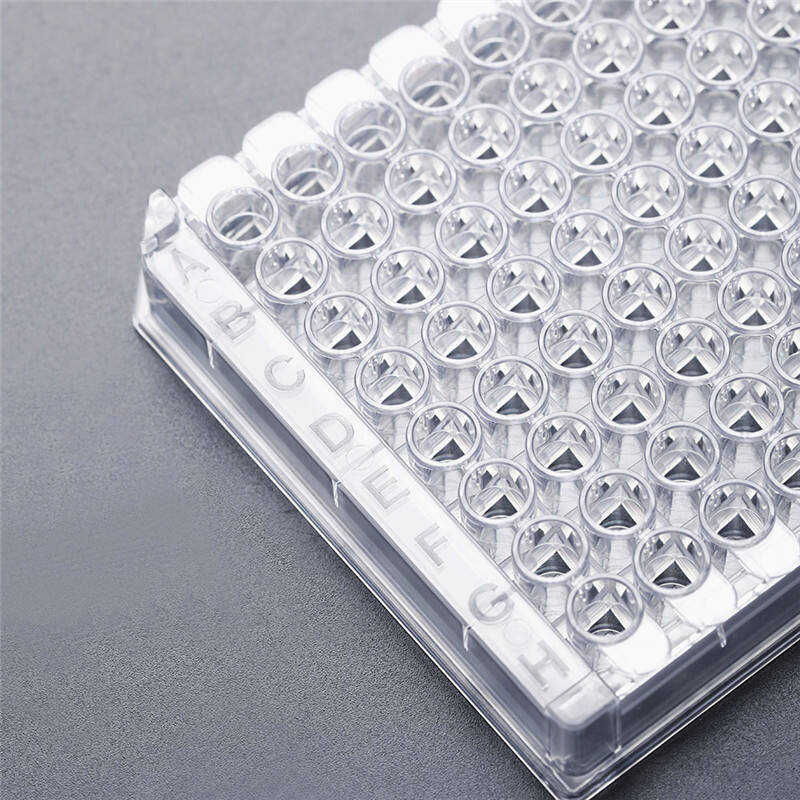

Most commercial ELISA plates on the market today are made from polystyrene because manufacturers love how easy it is to work with while still delivering good results. The material's thermoplastic properties make it ideal for injection molding processes, which means labs can reliably produce those standard 96-well and 384-well configurations needed for large scale testing. A recent report from the Polymer Applications Journal actually pointed out something interesting about polystyrene materials staying dimensionally stable even after going through harsh sterilization procedures like autoclaving or gamma irradiation. This stability matters a lot when dealing with lab equipment that needs strict quality standards. Compared to alternatives like glass or polypropylene, polystyrene keeps those flat optical surfaces intact so absorbance measurements come out accurate. Plus, it stands up better against common solvents such as methanol that show up regularly in various assay protocols across different research settings.

Key Physical and Chemical Properties Enabling Reliable Assay Performance

Polystyrene delivers an optimal balance of three critical properties:

- Surface hydrophobicity (water contact angle: 80–85°) facilitates passive adsorption of antibodies and antigens via hydrophobic interactions

- Chemical inertness prevents leaching of contaminants that could interfere with enzymatic detection systems

- UV transparency (90% light transmission at 450 nm) ensures compatibility with standard microplate readers

This combination minimizes background noise while supporting advanced surface modifications such as amine or carboxyl group activation for covalent immobilization strategies.

Binding Efficiency Comparison: Polystyrene vs. Polypropylene and Glass

IgG antibodies stick to polystyrene surfaces at around 300 to 400 ng per square centimeter, roughly double what we see on polypropylene at about 150 ng/cm². Glass does have better binding capacity over 500 ng/cm², but nobody wants to deal with broken glass plates or the light scattering issues they cause, especially in labs running hundreds of tests at once. What makes polystyrene so good? Its surface energy sits right around 40.7 mJ/m², kind of like finding the sweet spot between too sticky and not sticky enough. This Goldilocks effect means proteins bind well without getting all kinds of unwanted stuff sticking along with them. Makes a big difference when dealing with tricky samples such as blood serum or cell extracts where specificity matters most.

Protein Adsorption Mechanisms on ELISA Plate Surfaces

The efficiency of ELISA plate performance hinges on precise control of protein adsorption mechanisms. These surface interactions determine how effectively antibodies or antigens are immobilized, directly influencing assay sensitivity and reproducibility across clinical and research settings.

How Hydrophobic Interactions Drive Antigen-Antibody Immobilization

The polystyrene surfaces of ELISA plates work because they're naturally hydrophobic, which means they can grab onto biomolecules without needing any special treatment. These plates stick to biomolecules mainly through those weak van der Waals forces plus some non-polar interactions between molecules. What happens is that these plates latch onto the hydrophobic parts inside protein structures, creating a stable but not permanent bond. Looking at studies about how enzymes get attached to surfaces, physical adsorption methods seem pretty effective. For IgG antibodies specifically, around 85 to 90 percent bind initially when tested under normal lab conditions. That's actually better than what we see with ionic bonds or hydrogen bonds in most regular assays.

Surface Energy's Role in Maximizing Protein Binding Capacity

The way proteins spread out on well surfaces is basically controlled by surface energy, which we measure through contact angle tests. When plates are made with surface energies in the 40 to 50 mJ/m² range, they show about 30% more antibody sticking power than regular plates that haven't been treated. What makes this range special? It strikes a good balance between attracting proteins through hydrophobic forces but still keeps them oriented correctly so their important parts stay exposed where they need to be for recognizing targets. This matters a lot in lab settings where getting accurate results depends on these microscopic interactions happening just right.

When High Binding Isn’t Ideal: Balancing Sensitivity and Specificity

When too much protein sticks to surfaces, it tends to cause problems with non-specific binding, especially noticeable in blood samples from patients with certain antibody issues. Researchers have found that adjusting surface chemistry to control how many carboxyl groups are present cuts down on false positive results by about two thirds during sandwich ELISA tests. What's really impressive is that these modified surfaces still manage to catch over 95% of the actual targets they're looking for. Getting this balance right matters a lot in diagnosing autoimmune conditions and running complex lab tests where we need both good sensitivity and rock solid specificity at the same time.

Surface Treatments That Enhance ELISA Plate Performance

High-Binding, Medium-Binding, and Amination-Treated Surfaces Compared

Today's ELISA plates come with special coatings that adjust how things stick to their surfaces. Most labs use these high binding polystyrene plates, which according to some studies from 2023 account for around three quarters of what's available commercially. These plates work so well because they have those extra hydrophobic properties that grab onto stuff we want to detect, especially when looking for tiny amounts of things like cytokines in samples. Then there are medium binding versions too. They cut down on unwanted sticking by about forty percent compared to regular plates, which makes all the difference when working with messy biological samples full of different components. For folks dealing with negatively charged molecules, amination treatments add positive charges to the plate surface. This helps catch things like phosphorylated proteins or DNA bound to proteins much better than standard methods.

Carboxylated Surfaces for Optimized IgG Immobilization: A Case Study

The process of carboxyl functionalization actually produces those pH-sensitive spots where antibodies can stick together through covalent bonds. Research published last year showed some pretty impressive results when using these carboxylated ELISA plates instead of regular ones. They found about a 28% boost in how well IgG antibodies oriented themselves compared to just letting them stick passively. When conditions get slightly acidic around pH 5 to 6, those little carboxyl groups (-COOH) grab onto specific parts called lysine residues located in what's known as the Fc region of antibodies. What makes this so good is that it leaves the parts responsible for recognizing antigens completely free to work as they should. Tests on autoimmune diagnostic applications revealed something remarkable too. The variation between different tests dropped below 8% coefficient of variation, which beats out old school amination techniques both in terms of reliability and overall effectiveness according to findings from the Journal of Clinical Immunology back in 2023.

Design and Consistency Factors Affecting Assay Reliability

Well Geometry and Edge Effects in 96-Well Polystyrene Plates

Standardizing on the 96-well format does help cut down on evaporation issues across most of the plate. However, those wells along the edges tend to heat up or cool down about 12 to maybe even 15 percent quicker than others because they're just more exposed to the environment. We call this phenomenon the "edge effect," and it really messes with how reactions proceed over time. That's why good plate readers need to maintain pretty strict thermal control throughout the whole setup. To fix these problems, newer equipment comes with clever design features like sloped well walls and central raised areas. These modifications actually work pretty well at keeping tiny sample volumes stable while allowing better overall temperature balancing across all the wells.

Optical Clarity Requirements for Absorbance and Fluorescence Detection

The inherent optical clarity of polystyrene, which transmits over 92% of light at 450 nm wavelengths, makes it particularly well suited for colorimetric testing applications. When working with fluorescence measurements though, researchers need to go for ultra clear variants where the autofluorescence background stays below 5%. Surface treatment processes like gamma irradiation need careful handling to maintain these optical characteristics. If processing isn't consistent enough, cloudiness develops that can throw off OD readings by up to 0.2 absorbance units. This kind of distortion really impacts the reliability of experimental results in lab settings.

Ensuring Batch-to-Batch Consistency in Commercial ELISA Plate Production

Leading manufacturers keep track of around two dozen different material properties when producing these components. Important factors include things like how evenly distributed the polymer molecules are (with PDI values under 1.1) and making sure there's minimal leftover styrene monomer content, ideally below 50 parts per million. Recent research from 2024 showed that when companies use automated extrusion equipment, they can control thickness variations down to about plus or minus 2 micrometers. This results in batch-to-batch consistency where coefficients of variation stay well below 4 percent for protein binding capacity. Such stability matters a lot for long term experiments where researchers need plates to perform exactly the same way across months or even years of testing.

FAQ

Why is polystyrene preferred for ELISA plates?

Polystyrene is preferred due to its thermoplastic properties, ease of manufacturing via injection molding, dimensional stability after sterilization, and its ability to maintain flat optical surfaces for accurate absorbance measurements.

How does surface hydrophobicity of polystyrene benefit ELISA plates?

The hydrophobic nature of polystyrene allows for passive adsorption of antibodies and antigens through hydrophobic interactions, which is crucial for efficient assay performance.

How does protein binding compare between polystyrene, polypropylene, and glass?

Polystyrene offers higher binding efficiency for proteins than polypropylene but less than glass. However, glass presents issues like fragility and light scattering, making polystyrene the better practical choice.

What surface treatments enhance ELISA plate performance?

Surface treatments like amination and carboxylation can enhance performance by adjusting binding properties, reducing non-specific binding, and improving the capture of specific target molecules.

What are the optical clarity requirements for ELISA plates?

ELISA plates need to maintain high optical clarity for accurate absorbance and fluorescence measurements, often requiring post-production treatments to avoid cloudiness and ensure consistency.

Table of Contents

- Why Polystyrene Is the Preferred Material for ELISA Plates

- Protein Adsorption Mechanisms on ELISA Plate Surfaces

- Surface Treatments That Enhance ELISA Plate Performance

- Design and Consistency Factors Affecting Assay Reliability

-

FAQ

- Why is polystyrene preferred for ELISA plates?

- How does surface hydrophobicity of polystyrene benefit ELISA plates?

- How does protein binding compare between polystyrene, polypropylene, and glass?

- What surface treatments enhance ELISA plate performance?

- What are the optical clarity requirements for ELISA plates?