High Recovery SPE Extraction Tube for Environmental Monitoring & Pharmaceutical Analysis

- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

1. Product Introduction

-

Product Overview: The Extraction Tube by Xiamen Zhizi Industry & Trade Co., Ltd. is a top - tier laboratory consumable meticulously designed for sample extraction, separation, and storage in diverse scientific research, clinical testing, and biopharmaceutical applications. Engineered to meet the highest standards of performance and reliability, it serves as an essential tool in the complex processes of modern laboratories. With a comprehensive range of 8 different capacities, from 0.5mL for handling minuscule samples to 50mL for larger - scale extractions, it caters to the wide - ranging needs of various experimental procedures. Whether it's the extraction of nucleic acids in molecular biology research, the separation of serum in clinical diagnostics, or the purification of proteins in biopharmaceutical production, this Extraction Tube provides a secure and efficient solution.

-

Product Performance: Constructed from high - purity medical - grade PP or PET materials, our Extraction Tube exhibits outstanding chemical resistance. It can endure exposure to strong acids like 10% hydrochloric acid, strong alkalis such as 5% sodium hydroxide, common organic solvents like ethanol and methanol, and typical extraction reagents like guanidine salts and chloroform without any signs of dissolution or deformation. This ensures that the sample remains uncontaminated during the extraction process. The inner wall, treated with advanced "plasma polishing + silanization," has an ultra - low surface roughness of Ra≤0.1μm, resulting in an extremely low protein adsorption rate of <0.08μg/cm² and a nucleic acid adsorption rate of <0.03ng/cm². This significantly enhances the recovery rate of target substances, guaranteeing the accuracy of subsequent testing procedures.

2. Product Advantages

- Sterile Individual Packaging for Immediate Use and Contamination Prevention: Each Extraction Tube undergoes strict ethylene oxide sterilization, with a sterilization residue of <10μg/g, fully complying with the aseptic standards for medical devices (sterility assurance level ≥10⁻⁶). It is then packaged separately in an aluminum - plastic vacuum - sealed pouch, which effectively isolates it from air, moisture, and microorganisms. This design allows for immediate use without the need for additional sterilization steps. In scenarios where contamination control is of utmost importance, such as virus nucleic acid extraction in clinical diagnosis or cytokine extraction in aseptic experiments, this feature not only saves precious pre - processing time but also significantly reduces the risk of sample contamination. The aseptic environment maintained by the packaging ensures that the integrity of the sample is preserved from the moment of opening the package until the completion of the experiment.

- Full - Range of Sizes to Suit Diverse Extraction Requirements: We offer an extensive selection of 8 different capacity sizes for our Extraction Tube, including 0.5mL, 1.5mL, 2mL, 5mL, 10mL, 15mL, 30mL, and 50mL. The 0.5mL - 2mL sizes are ideal for handling minute samples such as oral swabs or single - cell suspensions, where precision and minimal sample loss are crucial. On the other hand, the 10mL - 50mL sizes are well - equipped to handle larger volumes of samples, like blood samples in clinical laboratories or soil extracts in environmental research. Additionally, we provide both transparent tubes for easy visual inspection of the sample state and brown tubes for light - sensitive samples, such as the extraction of vitamins or certain enzymes. This comprehensive range of sizes and options makes our Extraction Tube suitable for a wide variety of extraction applications across different scientific fields.

-

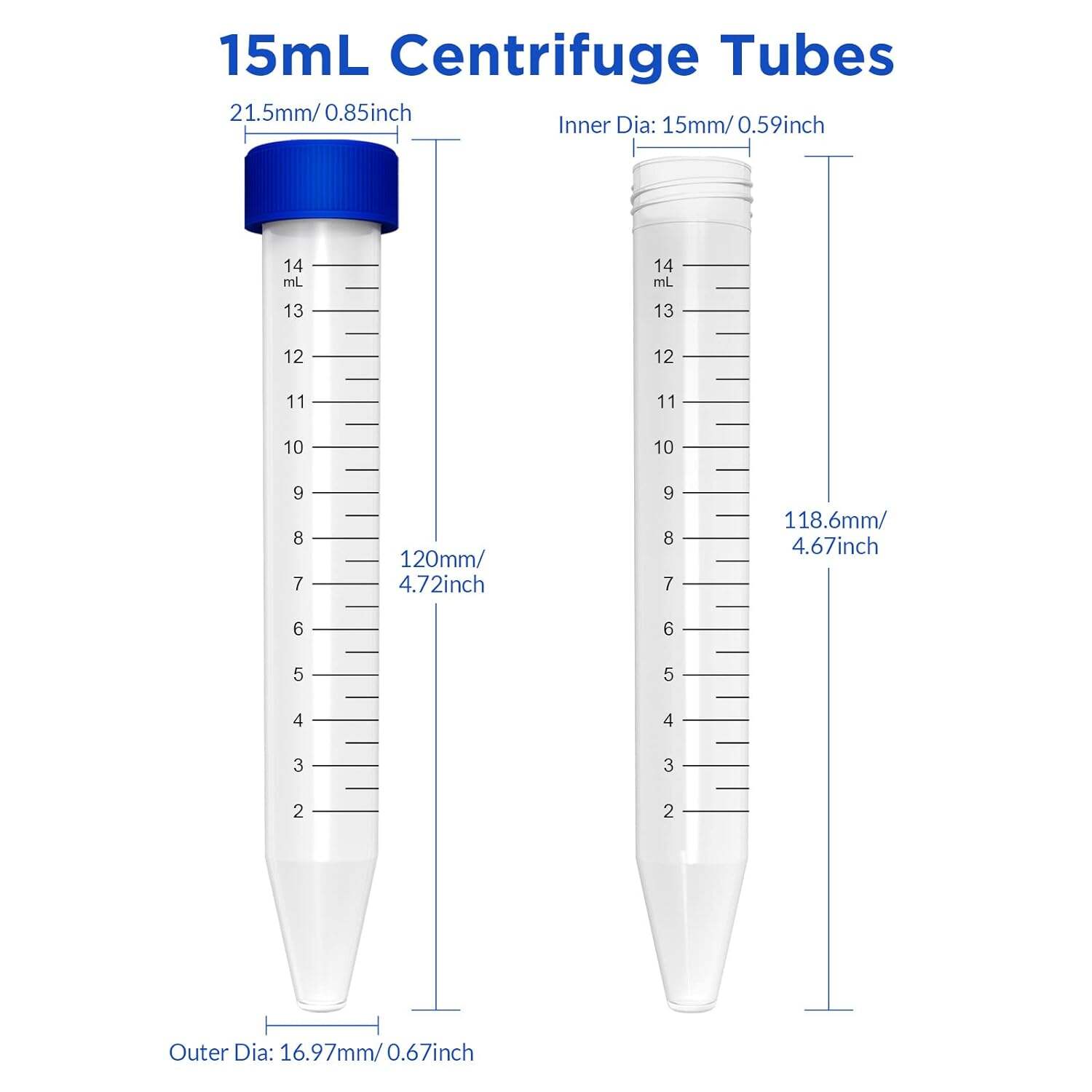

Compatibility with Automated Extraction Systems for Enhanced High - Throughput Efficiency: Our Extraction Tube is designed with dimensions that conform to ISO standards. For example, the 15mL size has a diameter of 17mm and a height of 120mm, allowing it to be directly used with mainstream automated extraction instruments in the market, such as the Qiagen QIAcube and Thermo Fisher KingFisher Flex, without the need to replace instrument adaptors or use custom - made consumables. Moreover, the tube body is equipped with a dedicated "barcode pasting area," which enables seamless integration with laboratory LIMS systems (Laboratory Information Management Systems) through barcode scanning. This integration not only facilitates sample traceability but also streamlines the automation process. In high - volume sample processing scenarios, such as in medical examination centers or third - party testing institutions that handle over 1000 samples per day, this compatibility significantly reduces manual intervention, improves processing efficiency, and ensures the accuracy and consistency of results.

3. Product Production Process

- Material Selection and Preparation: For the production of our Extraction Tube, we source only the highest - quality high - purity medical - grade PP or PET materials. These materials are carefully inspected for their chemical purity and physical properties before entering the production line. The PP material, known for its excellent chemical resistance and flexibility, and the PET material, valued for its high strength and transparency, are selected based on the specific requirements of different Extraction Tube models. Once the materials are approved, they are pelletized and prepared for the next manufacturing stage.

- Molding Process: The material pellets are then fed into precision injection - molding machines. These machines are programmed to precisely control the injection pressure, temperature, and cooling time to ensure that each Extraction Tube is molded to the exact specifications. For example, the tube walls are formed to a uniform thickness, with tolerances as low as ±0.1mm, and the dimensions of the tube, including its diameter, height, and the shape of the mouth and bottom, are maintained with high precision. The molding process also incorporates features such as the "20mm wide - mouth design" for easy sample transfer and the "conical - bottom structure" for efficient sample collection during centrifugation.

- Surface Treatment and Finishing: After molding, the Extraction Tubes undergo a series of surface treatment processes. The inner walls are treated with "plasma polishing + silanization" to achieve a super - smooth surface with a roughness of Ra≤0.1μm, reducing sample adsorption. The outer surfaces are polished to a smooth finish, and the tubes are laser - etched with precise scales, which are accurate to ±1%. Subsequently, the tubes are subjected to quality control checks, including inspections for any defects in the tube walls, seals, and scales. Finally, each Extraction Tube is sterilized using ethylene oxide and individually packaged in an aluminum - plastic vacuum - sealed pouch to maintain its sterility until use.

4. Frequently Asked Questions

Q: Can the Extraction Tube be autoclaved?

A: The PP - material Extraction Tube can generally be autoclaved at 121℃ for 15 - 20 minutes. However, it is important to note that the PET - material Extraction Tube is not suitable for autoclaving as it may deform under high - temperature and high - pressure conditions. Please refer to the product manual for specific autoclaving instructions based on the material of your Extraction Tube.

Q: How do I choose the right size of the Extraction Tube for my experiment?

A: If you are dealing with small - volume and precious samples, such as single - cell or micro - RNA extraction, we recommend using the 0.5mL - 2mL sizes. For general laboratory applications like blood sample separation or routine chemical extractions, the 5mL - 15mL sizes are often sufficient. For large - scale sample processing, such as in industrial - scale bioprocessing or environmental sample analysis, the 30mL - 50mL sizes are more appropriate. Consider the volume of your sample, the complexity of the extraction process, and the requirements of subsequent analysis when making your choice.

Q: Are the Extraction Tubes reusable?

A: Our Extraction Tubes are designed primarily for single - use applications to ensure the highest level of sample integrity and to prevent cross - contamination. However, in some cases where cost - effectiveness is a major concern and the samples are non - infectious and non - hazardous, the PP - material Extraction Tubes can be carefully cleaned and reused up to 3 times. But each reuse should be preceded by a thorough cleaning and sterilization process, and the tubes should be visually inspected for any signs of damage or wear before reuse.

If you are interested in our high - quality Extraction Tubes and would like to learn more about product specifications, wholesale prices, or customization options (such as custom - colored caps or logo printing), please leave your inquiry information (name, company, contact details, specific needs) on our official website. Our professional customer service team will respond to you within 24 hours, providing detailed technical documentation and tailoring a procurement plan to meet your specific requirements.