- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

1. Product Introduction

- Product Overview: The Centrifuge Tube developed by Xiamen Zhizi Industry & Trade Co., Ltd. is a high-performance laboratory consumable designed for sample separation, purification, and storage in molecular biology, clinical testing, and biopharmaceutical fields. Covering a full range of capacities (0.2mL, 1.5mL, 2.0mL, 15mL, 50mL), this Centrifuge Tube replaces traditional low-quality centrifugal containers, solving pain points such as sample adsorption, tube rupture under high speed, and difficult sample tracking. It is widely used in experiments like plasmid extraction, blood component separation, and cell supernatant collection, becoming an essential tool for optimizing laboratory workflows.

- Product Performance: The Centrifuge Tube excels in centrifugal resistance, sterility, and compatibility. Made of medical-grade PP/PC material, it tolerates 15,000rpm (PP) to 25,000rpm (PC) high-speed centrifugation without deformation. After gamma ray sterilization, it is free of DNase/RNase and pyrogens, meeting the strict requirements of molecular biology experiments. Its standardized dimensions perfectly match mainstream centrifuge rotors (e.g., Eppendorf 5424R) and automated workstations, reducing manual intervention. The inner wall, treated with anti-adsorption technology, minimizes protein/nucleic acid loss, ensuring sample recovery rate ≥98%.

2. Product Advantages

- Humanized Identification System for Efficient Sample Management: The Centrifuge Tube is designed with a dual identification system to simplify sample tracking. A 15mm×20mm frosted writing area on the tube body allows for clear marking of sample information (e.g., sample ID, collection time) with a marker pen—even after freezing at -80℃, the marking remains legible. Additionally, a dedicated printing area supports laser coding (e.g., 2D barcodes) and low-temperature-resistant ink printing, which can be scanned by automated laboratory equipment to link with LIMS systems. This design eliminates sample confusion caused by unclear marking, reduces manual data entry errors (error rate ≤0.3%), and enables efficient automated management of high-volume samples (e.g., 1000+ samples/day in clinical labs).

- Full-Series Sterility Assurance for High-Standard Experiments: The Centrifuge Tube undergoes strict gamma ray irradiation sterilization (dosage: 25-30 kGy), which penetrates the entire tube to kill 99.99% of microorganisms. Post-sterilization testing confirms it is free of DNase, RNase, and pyrogens—critical for preventing nucleic acid degradation and cell contamination in molecular biology experiments. For cell culture applications, select models of the Centrifuge Tube receive ultra-clean treatment (class 100 clean room processing), reducing particulate matter content to ≤1 particle/mL (≥0.5μm), meeting the high standards of cell culture and stem cell research. This sterility assurance eliminates the need for additional in-lab sterilization, saving experiment preparation time.

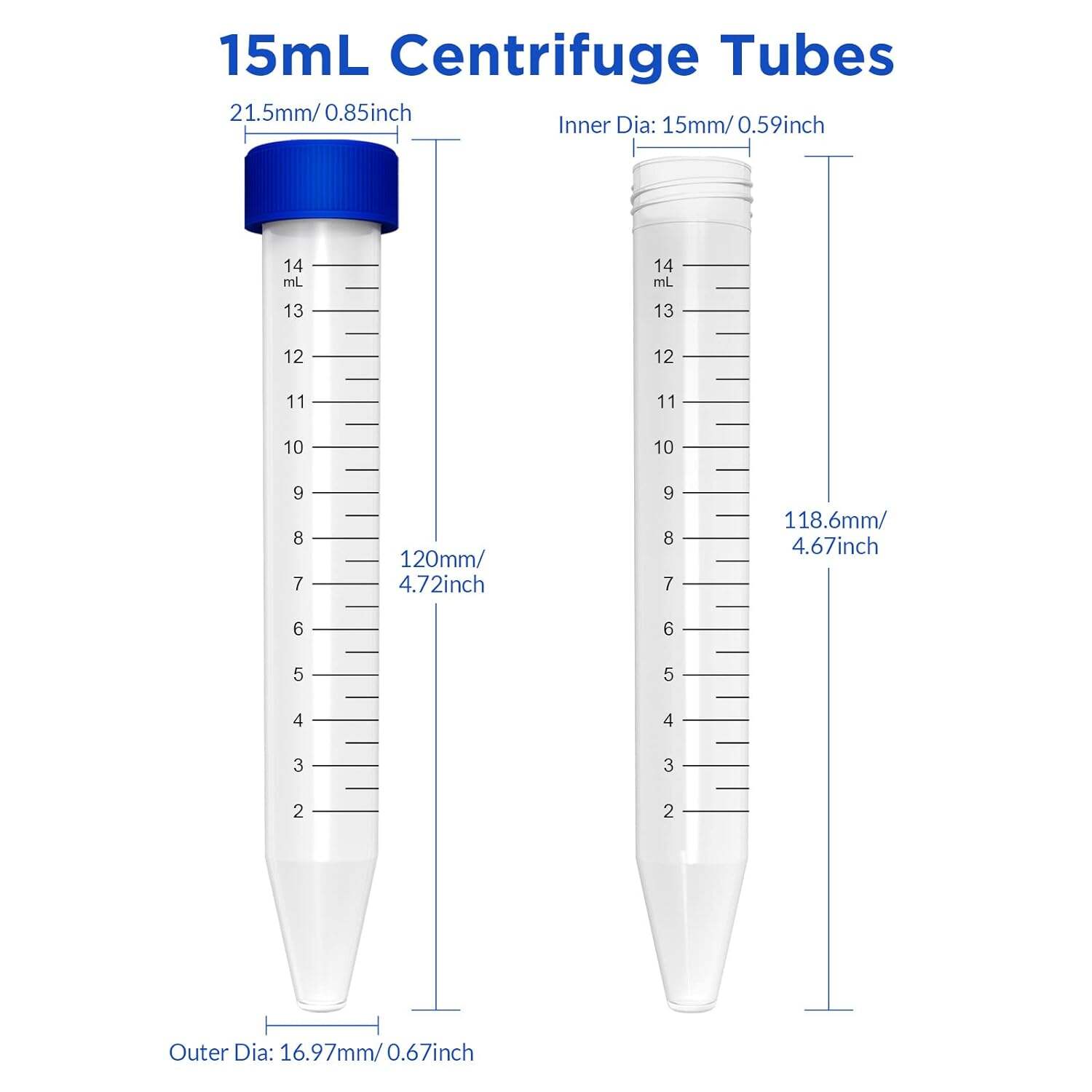

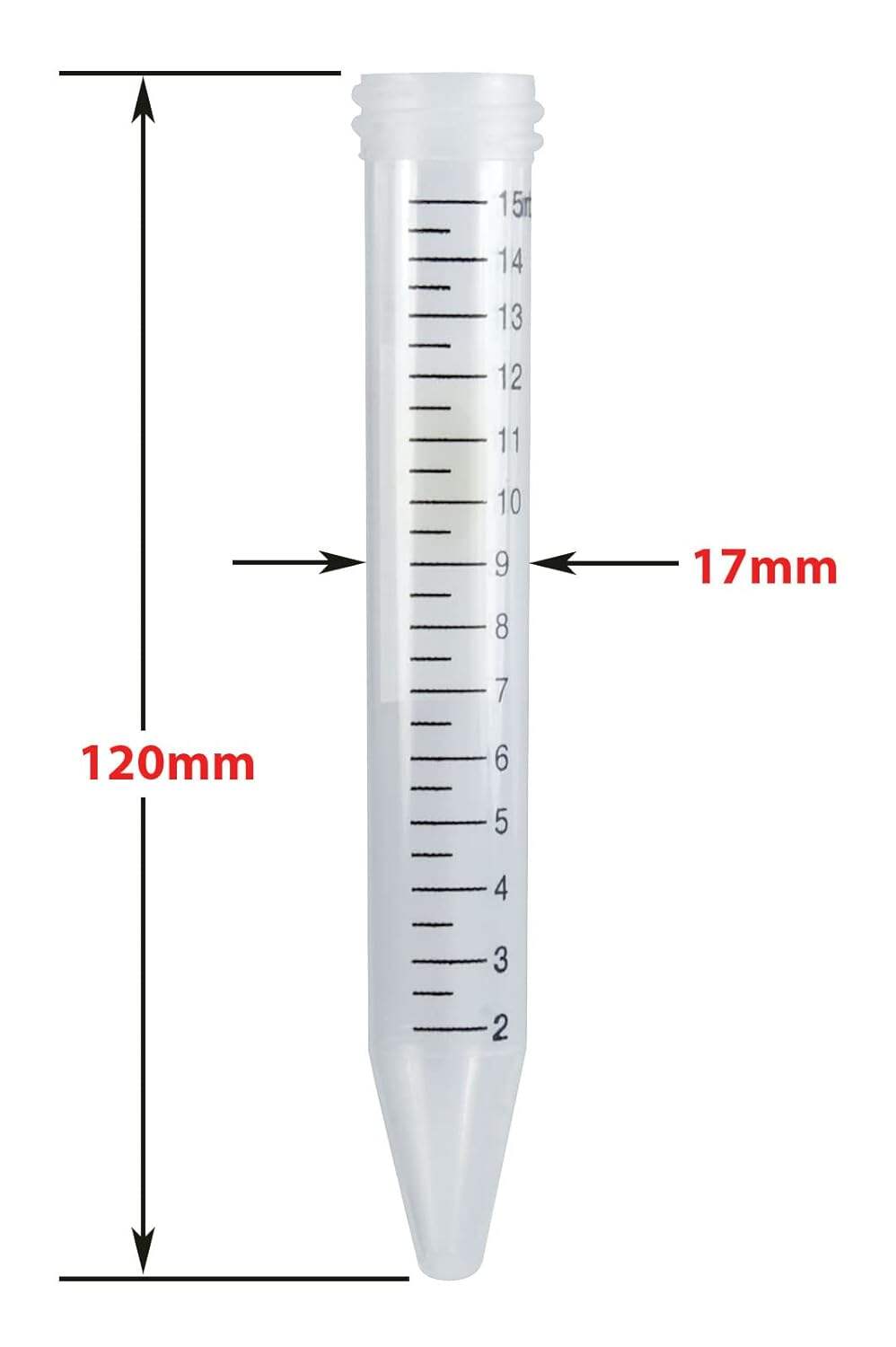

- Automated High-Efficiency Adaptation for High-Throughput Workflows: The Centrifuge Tube follows international standard dimensions for each capacity—0.2mL (6.5×28mm), 1.5mL (10×75mm), 2.0mL (10×78mm), 15mL (17×120mm), 50mL (27×115mm)—perfectly matching the adapter specifications of mainstream centrifuge rotors (e.g., Thermo Fisher Sorvall ST16) and automated workstations (e.g., Tecan Freedom EVO). It can be directly loaded into automated liquid handling systems for sample transfer, centrifugation, and detection without adjusting equipment parameters. For high-throughput labs, this adaptation shortens the experiment cycle by 40%, increases daily processing capacity by 30%, and ensures consistent results across batches.

3. Product Production Process

- Material Selection and Preparation: For manufacturing the Centrifuge Tube, high-purity medical-grade PP/PC materials are selected. Each batch of materials undergoes 8 quality inspections (including chemical purity, thermal stability, and biocompatibility) to ensure no DNase/RNase contamination. Qualified materials are melted into pellets and transported to the molding workshop, where they are preheated to 180-220℃ (PP) or 250-280℃ (PC) to prepare for the next step of producing the Centrifuge Tube.

- Precision Molding and Surface Treatment: The preheated material pellets are injected into precision molds via automated injection molding machines. The molds are customized for each capacity of the Centrifuge Tube, with a dimensional tolerance controlled within ±0.05mm to ensure standardized sizes. After molding, the Centrifuge Tube undergoes inner wall anti-adsorption treatment (plasma polishing + silanization) to reduce sample adsorption. The outer wall is processed to create a frosted writing area, and a smooth printing area is reserved for subsequent marking of the Centrifuge Tube.

- Sterilization, Quality Inspection, and Packaging: The molded Centrifuge Tube is transferred to a gamma ray sterilization chamber for 2-3 hours of irradiation. After sterilization, each Centrifuge Tube is tested for sterility (DNase/RNase detection, pyrogen test) and physical performance (centrifugal resistance, leak tightness). Qualified Centrifuge Tubes are laser-coded (if required) and then packaged into individual/boxed sterile packaging. Before shipment, a final random inspection is conducted to ensure every Centrifuge Tube meets quality standards—only the Centrifuge Tube that passes all tests is delivered to customers.

4. Frequently Asked Questions

Q: Can the PP-based Centrifuge Tube be autoclaved?

A: Yes, the PP-based Centrifuge Tube can be autoclaved at 121℃ for 15-20 minutes. However, it is recommended to use it no more than 3 times after autoclaving, as repeated high-temperature treatment may reduce its centrifugal resistance. The PC-based Centrifuge Tube is not suitable for autoclaving.

Q: What is the maximum centrifugal force (RCF) the Centrifuge Tube can withstand?

A: The PP-based Centrifuge Tube (15mL/50mL) can withstand a maximum RCF of 18,000×g (15,000rpm), while the PC-based Centrifuge Tube (1.5mL/2.0mL) can tolerate up to 30,000×g (25,000rpm). Specific RCF values for each capacity are detailed in the product manual.

Q: Is the Centrifuge Tube compatible with organic solvents (e.g., ethanol, DMSO)?

A: The PP-based Centrifuge Tube is compatible with ethanol (≤95%), DMSO (≤10%), and other low-concentration organic solvents. It is not suitable for strong acids (e.g., concentrated sulfuric acid) or chlorinated solvents. The PC-based Centrifuge Tube has better solvent resistance but should avoid contact with acetone. Test compatibility before use for special solvents.

If you are interested in our Centrifuge Tube and want to know more about product specifications (e.g., material options, packaging quantity), wholesale prices, or customization services (e.g., colored caps, custom logos), please leave your inquiry information (name, company name, contact number, specific needs) on our official website. Our professional team will reply to you within 24 hours, providing detailed technical documents and tailored procurement plans.