Why Airtightness Is Critical for Nucleic Acid Sample Integrity

Preserving Sample Integrity Through Effective Airtight Sealing in Nucleic Acid Sampling Tubes

Sampling tubes designed with strong air tight seals stop samples from coming into contact with the atmosphere, something really important for keeping RNA and DNA stable. When RNA gets exposed to moisture it breaks down fast. Research indicates degradation happens at around 3.2 times 10 to the minus 13th power per nucleotide every second under normal room conditions, and this breakdown speeds up even more in warm environments according to a study published in Nature back in 2013. Better sealing technology creates environments without oxygen and free from moisture that keep these molecules intact for many years. For anyone involved in long term storage of biological materials, this kind of protection matters a lot because even small problems with the seals can ruin valuable research data collected over several years.

Minimizing DNA Degradation Caused by Evaporation During Long-Term Storage

When tubes aren't properly sealed, samples tend to evaporate over time, cutting down their volume somewhere between 15 to maybe even 30 percent each year. This loss creates problems because it raises salt levels and increases nucleases, which basically speeds up DNA breakdown. Labs have found that samples left exposed will typically lose around 40% of those long chain DNA molecules within just half a year when stored at minus 20 degrees Celsius. The main culprit here seems to be this constant cycle of freezing and thawing that lets vapor escape. Fortunately, newer tube designs featuring double layer seals keep evaporation rates below 0.1% annually. These improvements help maintain proper concentration levels of various analytes, something absolutely essential for getting reliable results from PCR tests and sequencing procedures. Most labs now prefer these better sealed containers despite the higher upfront costs.

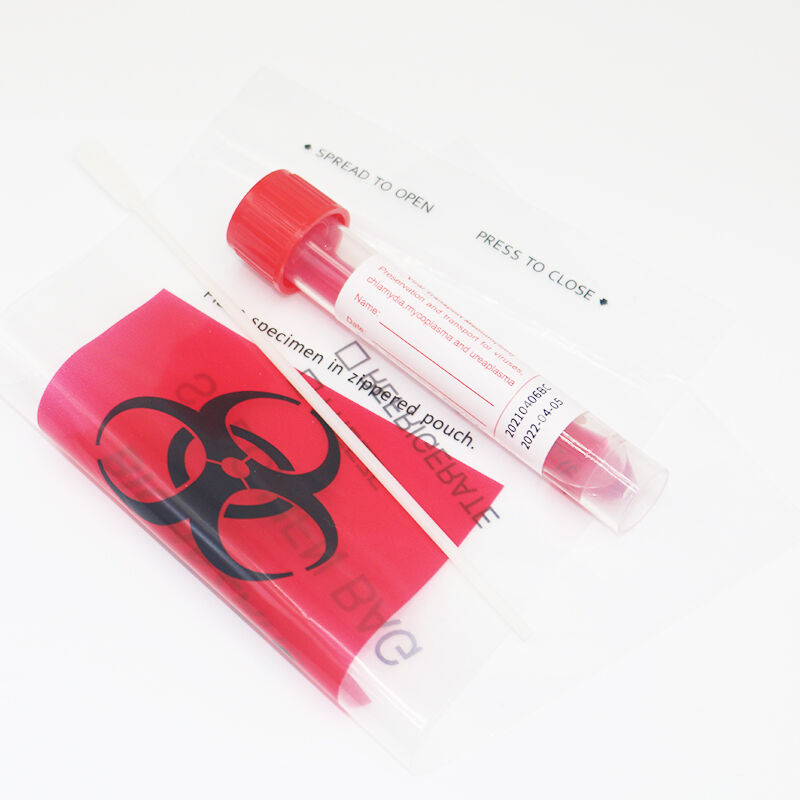

Preventing Cross-Contamination Due to Leakage or Poor Seal Performance

When samples leak during transportation or while being stored, they often pick up unwanted microbes and there's always the chance of losing valuable material. Tests conducted by third parties indicate that tubes with O-ring seals can stop leaks at around 99.9% effectiveness when subjected to pressures up to 40 psi. That makes them roughly three times better at preventing leaks compared to regular screw caps. For work involving sensitive materials such as viral genomes, these seals create a critical barrier against contamination from neighboring samples sitting next to them in racks. Without proper sealing, test results become unreliable and entire batches might need repeating, which wastes both time and resources.

Research demonstrates that precision-engineered seals extend nucleic acid usability by 10—15 years compared to conventional designs. When combined with appropriate materials, airtight sampling tubes reduce the need for repeat testing and support consistent outcomes across clinical and research environments.

Comparing Closure Types: Which Design Ensures Optimal Airtightness?

Choosing the right closure involves balancing security, ease of use, and environmental resilience. Below is an evaluation of four key designs and their performance in maintaining airtightness.

Screw Caps vs. Friction Seals: Balancing Security and Ease of Use

Screw caps tend to be the go-to choice when stakes are really high because of how they work mechanically. When those threads engage, they create even pressure across the entire surface between the cap and the tube's edge. For applications needing serious sealing power, manufacturers often go with multi-part designs featuring thermoplastic elastomer liners inside. These setups can create pretty much airtight seals as long as someone torques them correctly, which is why these types of closures hold up so well during extended storage periods. On the flip side, friction seals depend on tight fits between surfaces. They do allow for quicker handling since there's no threading involved, but this comes at a cost. There's always a bigger chance of leaks happening, particularly when dealing with super cold environments around -80 degrees Celsius. At such temperatures, materials actually shrink, and that shrinking messes with the fit, leading to potential failures down the road.

Thread Precision and Torque Consistency in Screw-Cap Reliability

Thread defects or inconsistent torque application significantly impact seal integrity. Studies show a 12% variance in torque reduces seal effectiveness by 34% in polypropylene tubes. To address this, automated capping systems now incorporate torque sensors (±0.15 N–m accuracy) to ensure consistent closure force without inducing stress fractures.

Evaluating Snap Caps for High-Sensitivity Applications

Snap caps offer rapid access and ease of use but present airflow challenges. Testing reveals average vapor leakage rates of 0.08% per hour at 25°C—acceptable for short-term handling but unsuitable for extended storage beyond 72 hours. Their suitability depends on workflow timelines and environmental controls.

Thermal Seals in Transport Scenarios

Heat induction seals provide permanent, tamper-proof closure, eliminating accidental openings during transit. Paired with aluminum foil backings, these laminated barriers reduce daily evaporation to less than 0.01%, making them optimal for interlab shipments lasting weeks. Their non-resealable nature suits single-use transport protocols requiring maximum sample security.

While each design serves specific needs, screw caps remain the gold standard for applications demanding sustained airtightness over time.

Key Sealing Mechanisms That Enhance Protection Against Leakage

Advanced sealing technologies integrate precision engineering and material science to maintain sample integrity under thermal shifts and mechanical stress.

The Engineering of Sealing Interfaces in Nucleic Acid Sampling Tubes

Effective sealing begins with micron-level manufacturing tolerances. Leading manufacturers use computer-controlled molding to achieve <2 µm deviation in thread profiles, ensuring uniform compression upon closure. A 2023 mechanical seal study found that tapered thread designs reduced vapor transmission by 62% compared to cylindrical counterparts, highlighting the importance of geometric optimization.

Role of O-Rings and Gasket Materials in Achieving Consistent Airtightness

Silicone PTFE composite gaskets have become pretty much standard equipment for high performance tubing applications. Why? Well they work across a wide temperature range from minus 40 degrees Celsius right up to 120 degrees. After opening and closing over 500 times, these gaskets still maintain about 92% of their original shape. And let's not forget their amazing resistance to helium leakage at just 0.003 cc per mmHg per day. Then there are those dual material O rings with their hard inner core wrapped in a flexible outer layer. These designs really stand up to cold flow issues when stored at ultra low temperatures something that recent experiments with retaining mechanisms has confirmed time and again.

Case Study: Leak Rate Comparison Across Five Leading Nucleic Acid Sampling Tube Brands

| Sealing Mechanism | Avg. Vapor Loss (72hr/4°C) | Pressure Resistance (kPa) |

|---|---|---|

| Screw Cap + Single Gasket | 1.2 µL/day | 220 |

| Snap Cap + O-Ring | 0.8 µL/day | 150 |

| Thermal Welded | 0.1 µL/day | 500+ |

Independent testing (N=1200) revealed thermally sealed tubes retained 98.7% of sample volume after 30 days, outperforming mechanical closures by 15–23%. This underscores the superiority of welded seals in preventing vapor loss and maintaining pressure resistance.

Material Selection for Long-Term Airtight Performance Under Stress

Polypropylene vs. Copolymer Blends: Stability During Freeze-Thaw Cycles

The type of tube material makes a real difference when it comes to how long seals last during temperature changes. Polypropylene tubes stay rigid even at -80 degrees Celsius, but they tend to crack easily after going through multiple freezing and thawing cycles. When labs mix polypropylene with other polymers like polyethylene, these copolymer blends show about 40 percent more stretchiness according to recent tests following industry standards from 2023. This extra give actually prevents tiny cracks from forming where the tube meets the seal. The improved flexibility is especially important for keeping RNA samples stable over time since any air leakage can ruin sensitive biological materials stored for extended periods.

Oxygen-Barrier Technologies in Advanced Nucleic Acid Stabilization Tubes

Advanced stabilization tubes fight against oxidative breakdown by adding special oxygen barrier layers made from materials like ethylene vinyl alcohol (EVOH) or silicon oxide coatings. According to research published in the Biopreservation Journal back in 2022, these barriers bring oxygen transmission down to less than 0.005 cubic centimeters per square meter per day. When manufacturers combine EVOH barriers with non-reactive gasket materials, samples stay intact at around 99.8% after sitting for 18 whole months. That's actually 27 percentage points ahead of regular polypropylene tubes when tested under accelerated aging conditions. The difference matters a lot for preserving sensitive biological samples over long periods.

Best Practices for Maintaining Airtightness in Automated and High-Throughput Workflows

Design Considerations for Preventing Evaporation in Automated Liquid Handling Systems

Automated workflows subject tubes to repeated mechanical stress and temperature fluctuations, increasing evaporation risk by up to 12% in unoptimized systems (2023 Laboratory Automation Report). Ideal robotic-compatible tubes feature:

- Low-deformation threading: Maintains seal integrity over 100+ open/close cycles

- Vertical alignment ribs: Prevent cap misalignment during robotic capping

- Vapor-tight secondary seals: Pressure-activated silicone gaskets compensate for minor tolerances

These features ensure reliable sealing performance in high-throughput environments.

Addressing Vapor Diffusion and Surface Tension Effects in Stored Samples

Even minimal vapor diffusion (0.1 µL/day) compromises DNA stability after one month. Advanced tubes mitigate this through integrated solutions:

- Hydrophobic inner coatings reduce surface tension by 40%, minimizing liquid creep into sealing zones

- Pressure-equalizing grooves allow safe venting during freeze-thaw cycles without breaking the seal

- Multi-angled cap seats establish three distinct sealing interfaces to block vapor migration paths

Tubes achieving <0.001% evaporation per day demonstrate how engineered sealing systems successfully balance automation compatibility with superior sample protection.

FAQ Section

Why is airtightness important for nucleic acid samples?

Airtightness is crucial to prevent moisture and oxygen from degrading RNA and DNA molecules, ensuring long-term stability and integrity of the samples.

What are the risks of poor sealing in sampling tubes?

Poor seals can lead to evaporation, loss of sample volume, increased salt concentration, and degradation of nucleic acids. It can also cause cross-contamination and loss of valuable research material.

Which sealing mechanisms are most effective?

Screw caps with thermoplastic elastomer liners and thermal welded seals are shown to be most effective, providing sustained airtightness and minimizing vapor loss.

How do advanced stabilization tubes work?

Advanced stabilization tubes employ oxygen barrier layers, such as ethylene vinyl alcohol or silicon oxide coatings, to minimize oxidative degradation and extend sample usability.

Table of Contents

- Why Airtightness Is Critical for Nucleic Acid Sample Integrity

- Comparing Closure Types: Which Design Ensures Optimal Airtightness?

- Key Sealing Mechanisms That Enhance Protection Against Leakage

- Material Selection for Long-Term Airtight Performance Under Stress

- Best Practices for Maintaining Airtightness in Automated and High-Throughput Workflows

- FAQ Section